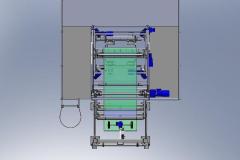

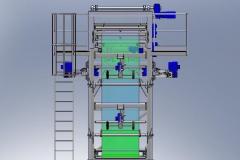

Stretch hood foiling (stretch hood machine)

Stretch hood machine an automatic packing machine, which in one cycle is formed with a hood and placed on the stretched film pelletized product. Stretch hood machine uses to work with inner sleeve tabs, made of stretch film. The packaging process is done on a cold-stretching the film. No additional heating to shrink.

Stretch hood machine is equipped with: automatic measurement of the amount of cargo, opening system and film application system and sensor that indicates the amount of film on the reel. We offer a variety of technological solutions depending on the type and capacity of pallets.

BENEFITS:

- high efficiency

- energy savings and lower operating costs

- no need for additional heating of the foil

- lower cost of unit packaging compared to a schrink hood

- possibility of installation into an existing production line

- high product stability on the pallet

- tight protection of the product against weather conditions

- minimizing the most common damage to cargo, such as loose packaging, crushing, flooding, etc.

- additional source of advertising

- foil with the company logo printed on it.

APPLICATION

High efficiency, shortening the time of packing a pallet, saving energy and reducing the cost of unit packaging are some of the advantages that make the Stretch hood packaging method continue to gain market share in various industries, such as:

- CHEMISTRY BUILDING INDUSTRY (cement, mortar, aggregates, paints, varnishes, enamels, emulsions, plasters, silicones, adhesives, fillers, grout, anti-corrosion products, gypsum board, wood panels)

- CHEMICAL INDUSTRY (fertilizers, sintered ceramics, resins, sulfur and many other products in drums, bags of cans and others)

- FOOD INDUSTRY (drinks in bottles, cartons products, toothpaste, salt, sugar, grain, animal feed, and many others)

- CERAMIC INDUSTRY (tiles and clinker, brick, silicates)

- OTHERS (appliances and electronics, garden soil, peat pellets)